Slot Dimensioning

If you are designing a ramp for a dog to get onto and off from the couch or a bed, you may use plastic sections with slots to snap the sections together.

A slot in a plastic molded part may have draft. This complicates how it should be dimensioned. Below is a best practice for how to dimension slots with draft.

The figure below shows our slot. Not only does it have draft, but it also has fillets and rounds.

We start with the goal of locating the the slot with a tolerance of position. Recall that a tolerance of position must be applied to a feature of size. That's easy if the slot has no draft. But our slot has draft. So we cannot define the entire slot as a feature of size. We need to pick a specific place in our slot to define as our feature of size. The top and bottom of the slot are not good places to define a feature of size because the top and bottom have corners that may or may not be sharp. This is why we go down a basic distance, a basic 10 in this case, from the top of the slot. This is where we will define our feature of size. Our size dimension says that at exactly 10 down from datum [A], the size must be 20 +/- 0.2.

Having established a feature of size, we can locate our feature of size with a tolerance of position. Our tolerance of position says that the center of our feature of size must fall within a 0.5 wide tolerance zone while holding the part on datum feature [A], and pushing it against datum features [B] and [C]. The slot is oriented to datums [A] and [B] and located to datum [C].

Everything we have looked at so far is specifically 10 mm away from datum [A]. Now we need to define the rest of the walls. We use a profile of a surface with a 0.1 wide tolerance zone. The profile of a surface does not locate the walls. They are located by the tolerance of position and the size tolerance. The profile of a surface controls the orientation and form. The profile tolerance zone will float within the size tolerance zone, and the profile tolerance zone will be exactly 99.5 degrees to datum [A] and exactly perpendicular to datum [B].

Finally we control the location, orientation, and form of the bottom of the slot with a profile of a surface that has a 0.5 wide tolerance zone. The tolerance zone is located and oriented to datum [A].

Dimensioning Drawings with AutoCAD – R Greenlee Page 6 Next we will add width dimensions to the right view. We will use the left face of the right view as a base datum and dimension from there. Click on the “Linear” dimension button and create a dimension from the left face to the left side of the slot. Dimensioning Geometrics is the science of specifying and tolerancing the shapes and locations of features on objects. Once the shape of a part is defined with an orthographic drawings, the size information is added also. The length (horizontal dimension of the slot): This has a feature size tolerance of ±0.5 mm and a position tolerance of 0.8 mm at MMC with respect to datum reference frame ABC. Following the logic of using slots, this feature has the highest tolerances.

The profile tolerance zones can float within the size tolerance zones. Each profile tolerance zone is independent of the other one. Each profile tolerance zone is two parallel planes 0.1 apart, exactly 99.5 degrees from [A] and exactly perpendicular to [B].

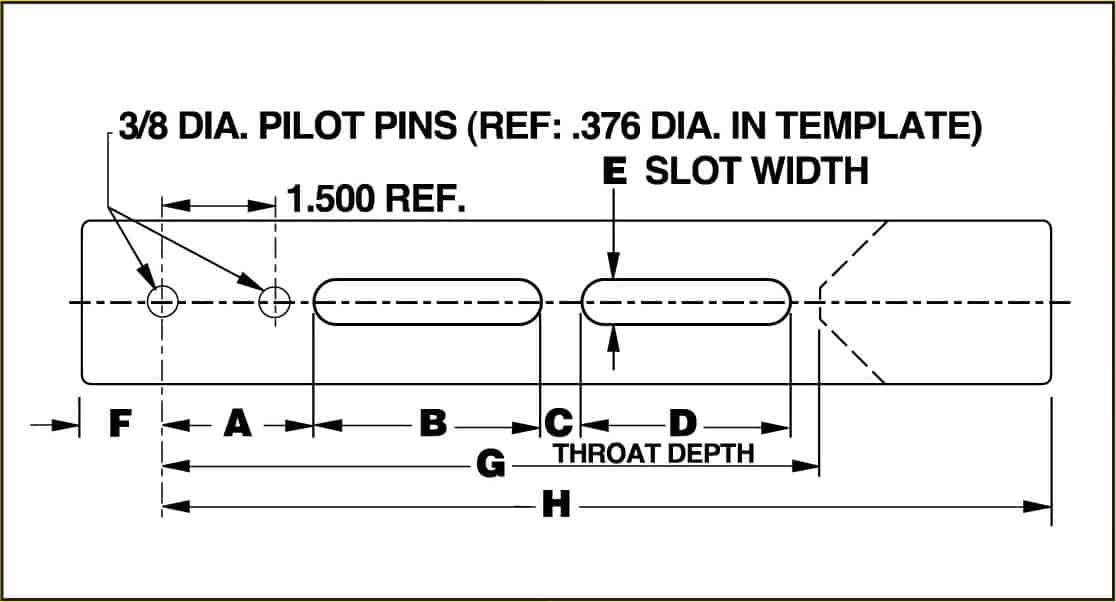

This information applies to the American Steel Industry.

Holes and Slots

Standard Holes

Standard hole sizes for bolts are made 1/16-in. larger in diameter than the nominal size of the fastener body. This provides a certain amount of play in the holes, which compensates for small misalignment’s in hole location or assembly, and aids in the shop and field entry of fasteners. In the absence of approval by the engineer for use of other hole types, standard holes shall be used in high strength bolted connections.

Although most holes for high-strength bolts are made 1/16-in. larger in diameter than the bolt body, certain conditions encountered in field erection require greater adjustment than this clearance can provide and approval from the engineer is required.

The maximum sizes of holes for bolts are given in the table below, except that larger holes, required for tolerance on location of anchor bolts in concrete foundations, are permitted in column base details.

Standard holes shall be provided in member-to-member connections, unless oversized, short-slotted or long-slotted holes in bolted connections are approved by the designer. Finger shims up to 1/4-in. may be introduced into slip-critical connections designed on the basis of standard holes without reducing the allowable shear stress of the fastener.

Oversize and Slotted Holes

When approved by the engineer, oversize, short slotted holes or long slotted holes may be used subject to the following joint detail requirements:

(1) Oversize holes may be used in any or all plies of connections in which the allowable slip resistance of the connection is greater than the applied load. Oversized holes shall not be used in bearing-type connections. Hardened washers shall be installed over oversized holes in an outer ply.

(2) Short slotted holes may be used in any or all plies of connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Short slotted holes may be used without regard for the direction of applied load in any or all plies of connections in which the allowable slip resistance is greater than the applied force. Washers shall be installed over short-slotted holes in an outer ply; when high strength bolts are used, such washers shall be hardened.

(3) Long slotted holes may be used in one of the connected parts at any individual faying surface in connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Long slotted holes may be used in one of the connected parts at any individual faying surface without regard for the direction of applied load on connections in which the allowable slip resistance is greater than the applied force. Where long-slotted holes are used in an outer ply, plate washers or a continuous bar with standard holes, having a size sufficient to completely cover the slot after installation, shall be provided. In high-strength bolted connections, such plate washers or continuous bars shall not be less than 5/16-in. thick and shall be of structural grade material, but not be hardened. If hardened washers are required for use of high-strength bolts, the hardened washers shall be placed over the outer surface of the plate washer or bar.

(4) Fully inserted finger shims between the faying surfaces of load transmitting elements of connections are not to be considered a long slot element of a connection.

Nominal Hole Dimensions

Anchor Bolt Holes

Hole sizes for steel-to-steel structural connections are not the same as hole sizes for steel-to-concrete anchorage applications. In the case of steel-to-steel connections, the parts are made in a shop under good quality control, so standard holes (bolt diameter plus 1/16″), oversized holes (bolt diameter plus 3/16″), and short and long-slotted holes can be used quite successfully. However, the field placement of anchorage devices has long been subject to more permissive tolerances (and often, inaccuracies that exceed those tolerances anyway and may require consideration by the structural Engineer of Record).

AISC published Steel Design Guide Series 1, Column Base Plates back in the early 1990s. At that time, it was recognized that the quality of foundation work was getting worse and worse. To allow the erector (and designer) greater latitude when possible, the permissible hole sizes in base plates were increased. These same larger hole sizes were included in the 2nd ed. LRFD Manual. The values there are maximums, not a required size. Smaller holes can be used if desired. Plate washers are generally required with these holes because ASTM F436 washers can collapse into the larger-sized holes, even under erection loads.

The larger hole sizes are primarily intended for the majority of base plates that transfer only axial compression from the column into the foundation. The anchor rods don’t usually do much after erection in that case.

To allow for misplaced bolts, holes in base plates are oversized. The AISC Manual of Steel Construction recommends the following oversized hole diameters for each bolt diameter:

Anchor Bolt Hole Dimensions

AISC, Steel Design Guide Series 1, Column Base Plates, suggests that using oversize holes meeting these criteria may still not accommodate field variations in anchor bolt placement and suggests adding 1/4 in. to the hole diameter listed. The guide recommends using a heavy plate washer over the holes. The AISC Structural Steel Educational Council cites the following example: “If bolts are misplaced up to 1/2 inch, the oversized base plate holes normally allow the base plate and column to be placed near or on the column line. If the bolts are misplaced by more than 1/2 inch, then corrective work is required.”

Slot Dimensioning Solidworks

Based on AISC oversize holes, the AISC Structural Steel Educational Council recommendations, and concrete contractor anchor-bolt placement techniques, ASCC (American Society of Concrete Contractors) concrete contractors recommend the following tolerance for each bolt location:

Dimensioning A Slot Solidworks

- 3/4-in. and 7/8-in. diameter bolts: ±1/4 in.

- 1-in., 1-1/4-in., and 1-1/2-in. diameter bolts: ±3/8 in.

- 1-3/4-in., 2-in., and 2-1/2-in. diameter bolts: ±1/2 in.

Ansi Slot Callout

End of article.